Prototype Delivery 7-10 days

1000pcs Delivery 20days

Hyer focuses on online CNC machining parts and provides one-stop CNC machining services, including CNC turning, milling, EDM, Five-axis machining, and complete surface finishing. You will receive the products within one week if you request an online quote today.

As one of the leading CNC machining companies, having a professional engineering team is very important for us. We have 3/4/5 axis CNC machining centers, turning, lathe, cutting and milling machines, and EDM. But more importantly, we have a very professional operation team that provides custom CNC machining solutions. With these machines, all the equipment is used to the maximum, so the products produced in our factory have a low error rate. We hope to use all our experience to help turn your design into a real product. Hyer CNC machining manufacturer is looking forward to your contact.

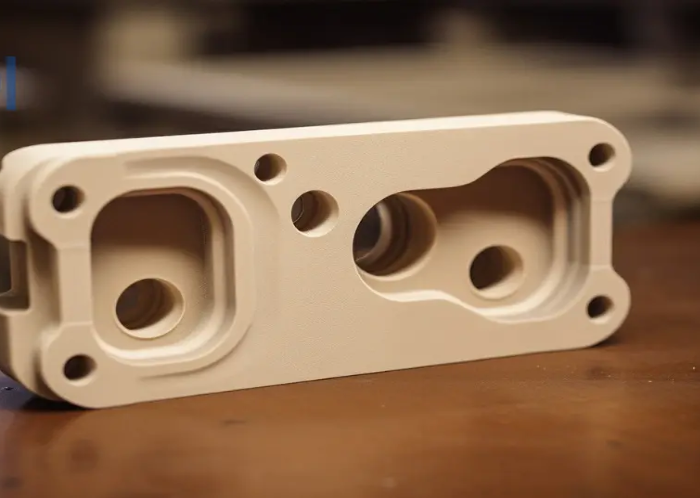

CNC machining centers can always make very complex products. CNC turning and milling have different advantages in the machining industry compared to multi-axis machining.

The machine tool makes it easier to shape the product quickly. From the development of multi-axis machine tools to the present, too many high-precision, small CNC mills for the machinability of aluminum, large aluminum plates, and complex products have been produced.

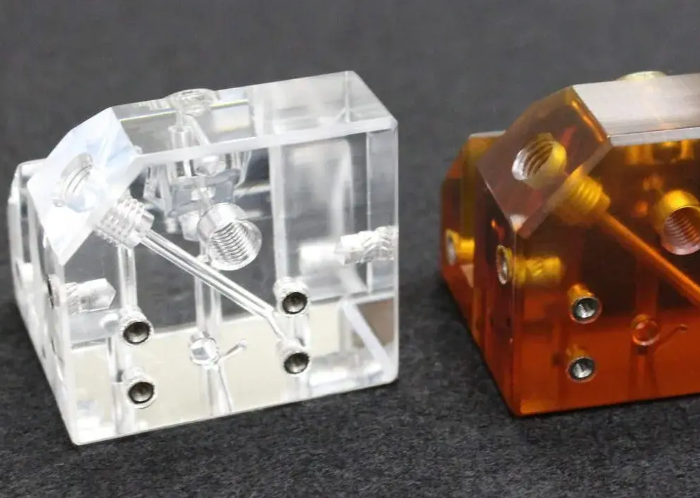

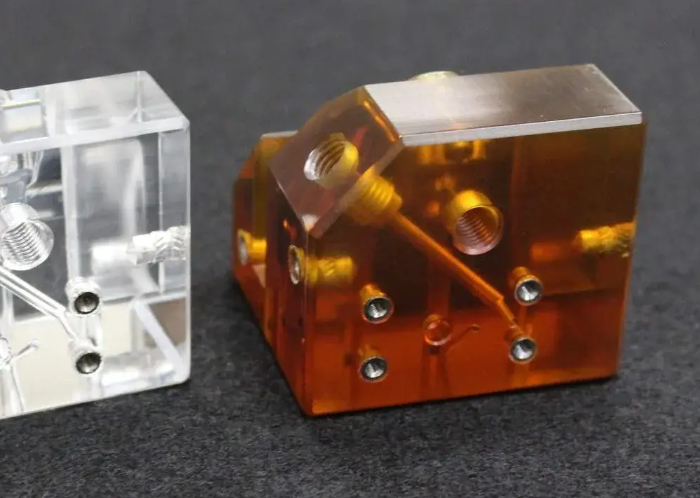

We also make a large number of molds and can process aluminum, brass, stainless steel, plastic, magnesium alloy, and so on.

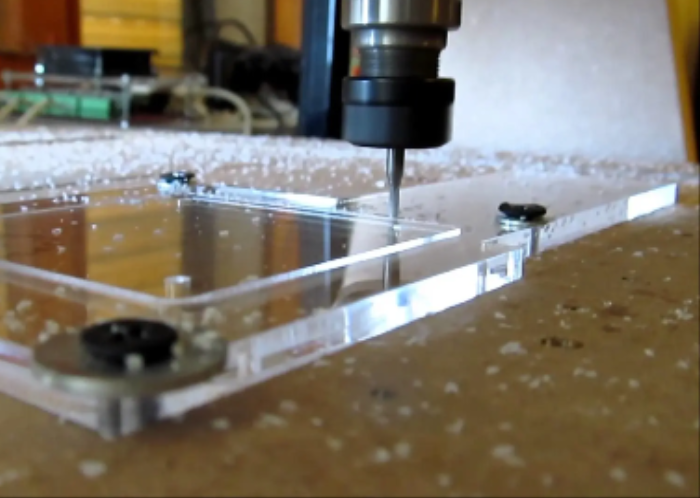

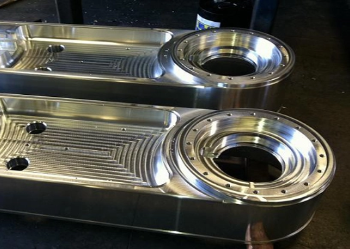

CNC milling is a manufacturing process. It uses computer numerical control (CNC) to control machine tools and remove material from metal or other hard materials. CNC milling uses a computer program to set production instructions and paths for a workpiece. The milling machine’s cutting tools then move along these paths to accurately cut and shape the material. This technology is capable of producing parts with complex shapes and tight tolerances and is widely used in the automotive, aerospace, medical device and electronics industries. CNC milling provides greater precision, efficiency and repeatability than traditional manual operations, always offers huge advantages for high volume orders.

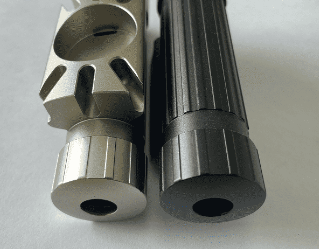

CNC turning is a precision machining process. It mainly produces symmetrical axis components like spirals, bearings, shafts, and discs. This process relies on a computer numerical control (CNC) lathe. It uses the lathe to create the shape by rotating the workpiece. It cuts along many axes with a tool. CNC turning enables high-precision and high-complexity designs. Computer control systems ensure the quality and sameness of each part. This method improves efficiency and reduces human error. It’s widely used in industries requiring high-precision parts, like automotive, aerospace, and medical equipment.

The processing principle of EDM machine tools is a nontraditional material processing method based on electric spark discharge. Its core uses pulsed spark discharge between the tool electrode and the workpiece. The metal is then melted and vaporized at high temperatures to achieve processing purposes.

EDM processing is suitable for processing high-hardness materials and complex-shaped molds and parts. It is also commonly used for material cutting and grooving. If the tool breaks inside the product hole during processing, we can also remove it with EDM processing.

EDM is an excellent choice for processing small parts, volatile parts, and sharp corners. It can also achieve a high precision of 0.005mm and is often used in combined processing with CNC.

The preferred choice for CNC machining of aluminum materials. Advantages of aluminum include: corrosion resistance, high hardness, low density, good processing and sealing performance, environmental protection and energy saving, good decoration and conductivity, wide application range, good ductility, etc.

Common aluminum alloy materials:

|

|

Steel is widely used in the machinery manufacturing industry. It can be used to manufacture various mechanical parts, such as bearings, gears, racks, engine parts, furniture, agricultural machinery, lamps, electrical equipment, and connecting parts. Steel’s high strength and excellent processing properties enable machinery to operate normally and withstand high-intensity loads.

Common steel alloy materials, such as:

|

|

Brass has good cutting properties and easily performs common machining operations such as drilling, milling, turning, and cutting. This enables high-efficiency, high-precision machining. The zinc component in brass alloys can improve the hardness and wear resistance of the alloy. This makes the processed products less prone to wear and tear during long-term use.

Common brass material:

|

|

Stainless steel is often divided according to its organizational state: martensitic steel, ferritic steel, austenitic steel, austenitic-ferritic (duplex) stainless steel, precipitation-hardened stainless steel, etc. In addition, it can be divided according to its composition: chromium stainless steel, chromium-nickel stainless steel, chromium-manganese-nitrogen stainless steel, etc.

Common stainless steel:

|

|

Red copper has good electrical and thermal conductivity and corrosion resistance. It also shows good plasticity and forgeability during mechanical and thermal processing.

Red copper is often used to make electronic components. Because of its unique color, it is often used in CNC processing for various decorative products.

Titanium alloys are stronger than many traditional materials, but their density is lower. This makes them ideal for weight reduction in aerospace and automotive manufacturing areas.

Titanium also has good corrosion resistance, high hardness, non-magnetic properties, and heat resistance. These unique characteristics make titanium alloys widely used in aerospace, medical equipment, the chemical industry, marine, and other fields.

Kupplungsgehaeuse-polygon cnc turning and milling machining aluminum parts

Product Name :Kupplungsgehaeuse-polygon

Material: AL7075-T6

Processing: CNC machining ,Sand blasting , Blue anodized

Lead Time: 7days

Quantity: 60pcs

CNC machining (computer numerical control machining) is simply a processing and manufacturing method that subtracts metal or plastic materials. It uses a computer to write code and process it through CNC machine tools to get the required customized machined parts.

Engineers use UG (Unigraphic), Mastercam, Hypermill, and other programming software to write a series of programs on CAD drawings. This allows us to design the fixture that matches the product, debug the machine, and realize product processing.

During this process, engineers will optimize tool paths to improve processing efficiency. This can improve the ability to design fixtures for simple products, allowing one-time programming to process multiple products. This saves processing time and thus reduces processing costs.

CNC machine tools are usually divided into turning machines and milling machines (3-axis, 4-axis, 5-axis machines). Hyer, with complete equipment, can achieve one-stop product processing.

We stand out in the CNC machining industry with the following advantages:

1. Our company has a large number of experienced engineers with more than ten years of experience, and we also have a very professional international sales team.

2. CNC machining manufacturing has undergone strict quality inspection and strictly follows ISO standards. We also have advanced machines for more sophisticated CNC machining custom production services.

3. We have a team of quotes, CNC, sheet metal, 3D printing, injection molding, etc., all of which are reviewed by a professional engineering team. You will get a quote within 24 hours.

CNC milling machining is vital in manufacturing aerospace components and standardizing the process. Aerospace equipment uses a variety of hard metals and specialty materials to create parts ranging from decorative to critical functions. CNC milling can better complete difficult-to-machine materials, such as nickel-chromium super alloy Inconel and 17-4PH stainless steel. CNC Milling is also essential for the manufacture of precision steering equipment.

Machine shops also use CNC milling machines to make many of the parts used to manufacture agricultural equipment. CNC machining manufacturing has large-scale, short-term production capacity.

The energy industry uses CNC machining to mass-produce components for various applications. Nuclear power plants require delicate parts, and the gas and oil industries also rely on CNC machining to produce the parts that keep fuel flowing. Hydropower, solar, and wind energy providers also use CNC milling and turning to manufacture system components that ensure continuous power generation.

Another industry that requires tight tolerances for safety-critical applications of CNC lathes is the oil and gas industry. This department uses CNC milling machines to manufacture precise and reliable parts such as pistons, cylinders, rods, pins, and valves.

These parts are often used in pipelines or refineries that may require small quantities or specific quantities of products. The oil and gas industry often requires corrosion-resistant machinable metals such as 5052 aluminum.

Medical manufacturers use CNC mills and lathes to create essential medical equipment and tools, such as prosthetics, that need precise and unique designs.

CNC machining enables medical devices to keep precise design features on various metal and plastic substrates and quickly create components and products. This helps companies stay ahead of the medical technology curve.

Because the CNC machining process is suitable for one-off custom parts, it has many applications in the medical industry. The tight tolerances offered by CNC machining are critical to high-performance machining of medical components.

Mechanical automation and intelligence are becoming increasingly popular. Many automation industries need to be designed and customized according to customer requirements to meet customers’ different needs. All technology requires precision to work properly. A CNC milling machine follows the design to the final detail. This ensures that products with multiple parts and layers can be assembled quickly without errors or misalignment.

At the same time, CNC milling is fast and convenient. You only need to set up the machine, and the parts can be milled quickly according to the settings. CNC can also create a variety of replacement parts. This is because the turnaround time is fast, and no minimum required part quantity is required.

ISO 2768 Tolerances of CNC Machining Services

We will process according to the tolerances in the customer’s PDFdrawing. If there is no PDF or DWG drawing, you can also use the industry standard ISO 2678 toerance. If there are some important tolerances, you can explain them directly . See the ISO 2678 tolerance table below .(Calculate the tolerances of shafts and holes)

| Tolerance Lever | Overall Dimension Range | ||||||

| Specifications | <<3,>0.5 | <<6,>3 | <<30,>6 | <<120,>30 | <<400,>120 | <<1000,>400 | <<2000,>1000 |

| Tolerance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |