Hyer Mold specializes in the manufacture of custom precision molded rubber parts for many applications. From the development and testing of prototypes to the full-scale production of custom rubber parts, our experienced team has an intense commitment to every customer to ensure quality products and services our customers can trust. We provide OEM and aftermarket custom rubber parts across a wide range of industries while meeting the highest quality standards.

Hyer Mold specializes in custom precision molded rubber applications for the defense, military, aerospace, government, nuclear, food processing, life sciences, medical instruments, pharmaceutical, biopharmaceutical, pump, and semiconductor industries. Some of the most prevalent product applications include:

Hyer Mold thermoset elastomers to produce seals used in numerous applications to prevent leaks or contamination. Available materials include:

|

|

|

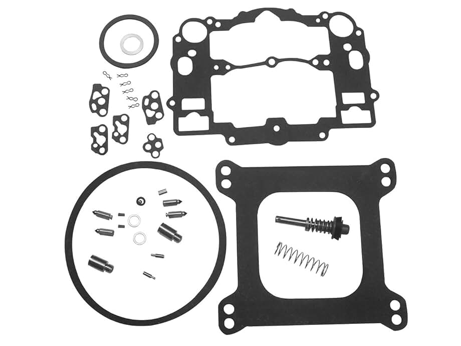

O-rings are one of the most widely recognized rubber seals in the engineering industry, used in valves, cylinders, pumps, and connectors to prevent fluids and gases from leaking. An O-ring is a circular seal used with static, dynamic, hydraulic, and pneumatic components by sitting in a specially engineered groove and becomes compressed when two or more parts interlock. O-rings’ key strength is their ability to return to their original shape after removing the compression forces acting on them, making them an economical and reliable solution for sealing applications in aerospace, defense, nuclear, food processing, medical device, and pharmaceutical industries.

Rubber gaskets mechanically seal the microscopic gap between two joints or mating surfaces of nonmoving parts. Rubber gaskets are highly resilient in low temperature and pressure sealing applications and mild chemical environments. When compressed, rubber gaskets offer an excellent seal between two surfaces, preventing leaks or contamination.

Common applications for rubber gaskets include:

- Medical Industry: Used in medical devices, including catheters, tubing, IV bags and o-rings.

- Food and Beverage Industry: Used in processing plants to ensure sanitation and safety, including mixers, ovens, bottle sealing, pasteurization and o-rings.

- Other Industrial Uses: Pumps, valves, and conveyors.

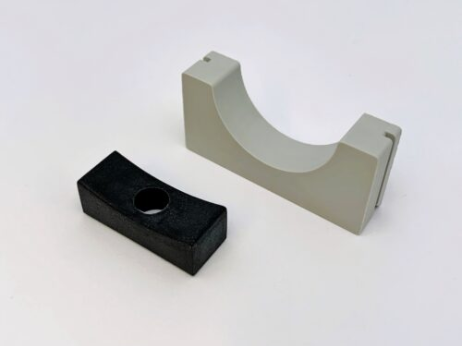

A variety of industries use rubber grommets to strengthen or protect an opening with sharp edges or provide insulation for an object passing through the opening. Grommets can help reduce vibration and protect important wires and cables from chafing or grazing on rough surfaces.

Grommets are used in the following applications:

- Aerospace Aircraft Interiors: including inside the cabin and galley, seat armrests, and window blinds.

- Military and Defense: for electrical insulation, noise control, and windshield sealing.

- Industrial wire and cable systems: such as surge protectors, wiring outlets, and manifolds.

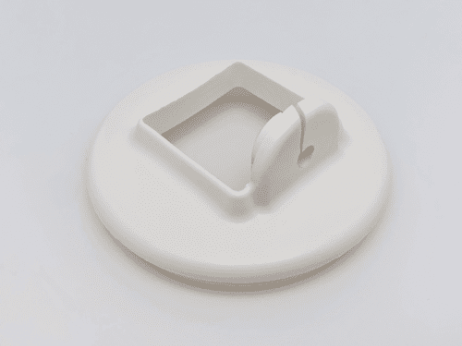

Rubber latches are beneficial for harsh environments that are not suitable for metal parts. Rubber latches offer more flexibility over metal and are rust, corrosion, and UV resistant. Many aerospace and marine applications use rubber latches.

Common rubber latch applications include:

- Aircraft doors and hatches

- Latches on various military transporters and vehicles, remote control vehicles, and autonomous vehicles.

Rubber valves are essential for precision and complex flow control, used in multiple cooling and hydraulic control systems. The medical industry widely uses rubber valves for disposable IV fluid delivery systems, fluid dispensers, and tubing circuits for heart surgery.

Rubber diaphragms are flexible membranes offering a simple, durable sealing solution between two chambers. The two distinct types of rubber seals include static, which separates mediums in low- to no-motion applications, and dynamic, which seals nonmoving and moving components in a flow system. The aerospace industry uses rubber diaphragms for many applications, such as pumps, control devices, regulators, meters, and air and gas compressors.

With extensive rubber molding capabilities, Hyer Mold is known for delivering custom molded rubber parts with exacting tolerances for many demanding industries and critical to function applications, including:

|

|

|

|

Hyer Mold utilizes compression, transfer, injection, liquid silicone rubber molding, and rubber to metal bonding manufacturing processes to produce custom-engineered products used in mission-critical applications. Example product applications include seals, O-rings, diaphragms, gaskets, grommets, valves, poppet assemblies, plungers, boot pads, latches, flappers, vacuum cups, switches, shells, covers, housings, cases, connectors, and buttons.

With Hyer Rubber’s various rubber molding services, we can create the custom rubber parts mentioned above that meet our clients’ exacting tolerances and custom requirements. Contact us to learn how we can help with your rubber component needs or request a quote today.